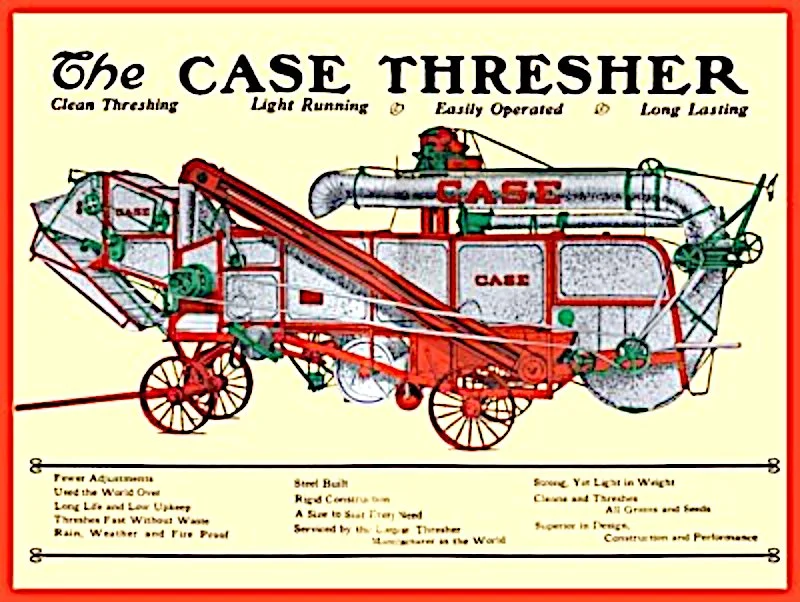

Case Threshing Machine

Our 1884 belt drive Threshing Machine

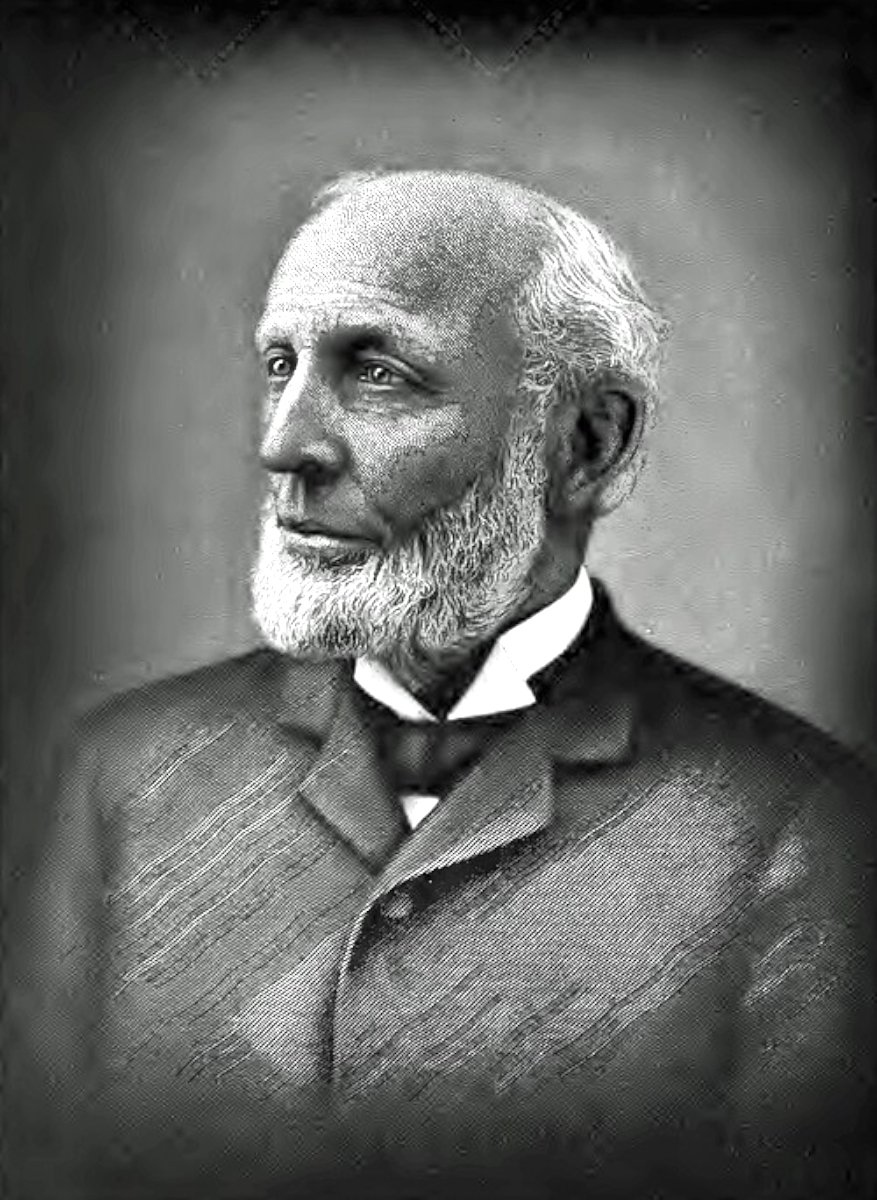

Jerome Increase Case

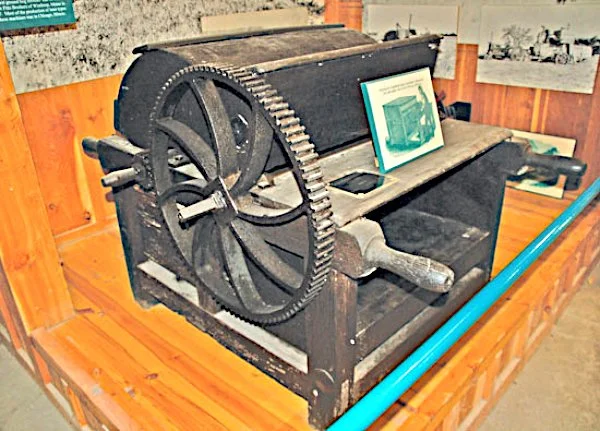

Caleb Case, Jerome’s father sold some primitive "ground hog" machines (see below) that helped speed up the separation of grain after it was harvested. In 1840, Jerome started a small business threshing his neighbors' crops with a horse-powered thresher.

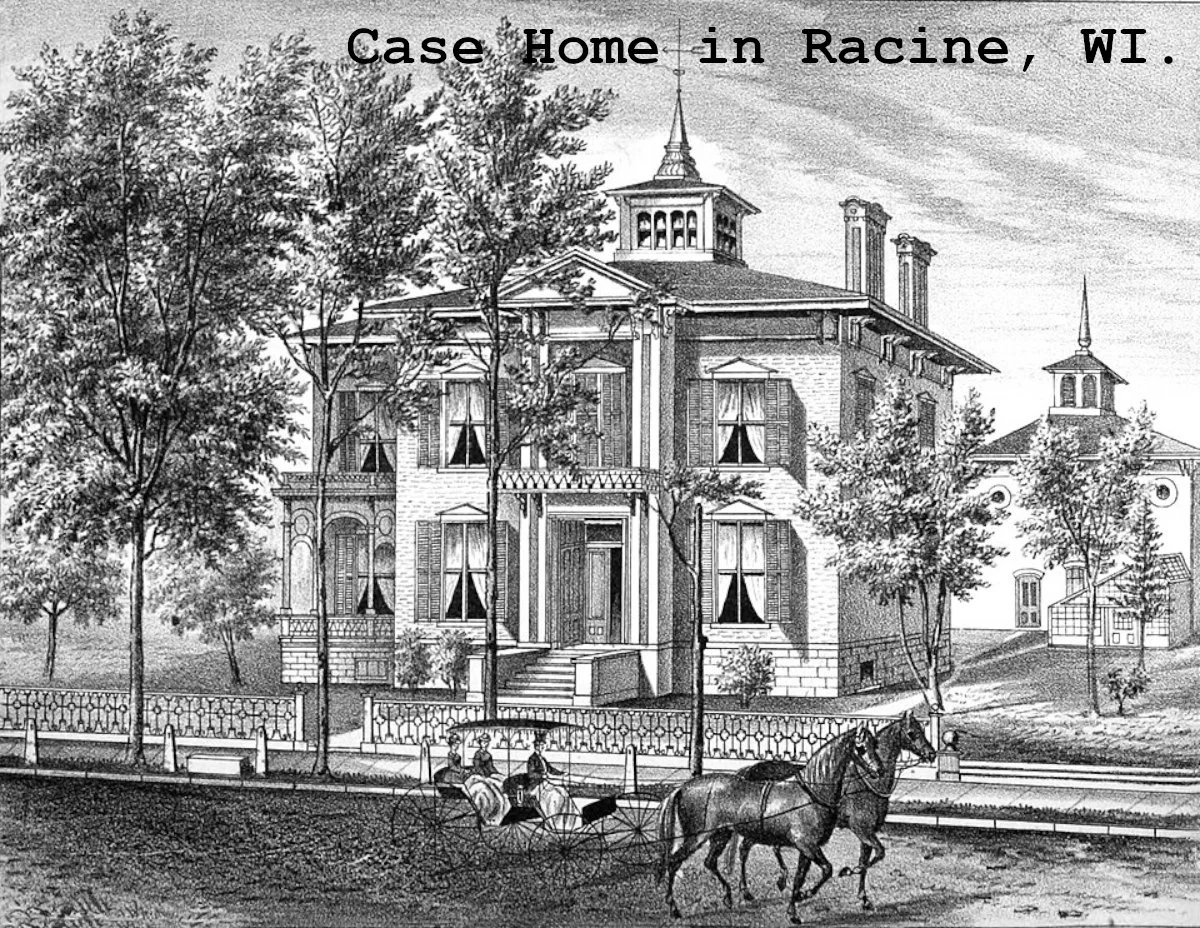

In the summer of 1842, he bought six horse-powered machines on credit and traveled first to Chicago by ship. On his way north to Rochester, Wisconsin he sold five and kept one for his own business. Through the winter he worked on improvements to the thresher, but the new model was not ready for the 1843 harvest. By May 1844, the new model which did a better job of fully separating the grain was working. Since Rochester did not have water power available, he moved to Racine, Wisconsin.

J I Case Threshing Machine Company

The Company was Founded in 1842 by Jerome Case as the J. I. Case Threshing Machine Company, it operated under that name until 1928. For 66 years after that it was the J. I. Case simply Case.

In 1856, Jerome Case was elected mayor of Racine. He declined the re-nomination the next year but was elected again in 1858 and 1860.

He often financed the machines with high interest rates. This worked until the panic of 1857 and unreliable state-issued paper money caused many customers to default. Case accepted animals, supplies, and land instead of cash.

Massena B. Erskine, Robert H. Baker, and Stephen Bull (his brother-in-law) became partners when J. I. Case Company was officially organized in 1863. Case was elected to the Wisconsin State Senate in 1865 and served one two-year term.

In 1884, Case made a visit to a farm named after him in Minnesota upon receiving news that one of his thresher machines was not working. Infuriated by the fact that he could not fix the machine himself, he set it ablaze the next day and sent the owner a brand new thresher machine upon return to Wisconsin.

In 1890, the Case Company expanded to South America, opening a factory in Argentina. In 1891, Jerome Case died.

In 1904, Case introduced the first all-steel thresher machine. Case sold their first gasoline tractor that year and established a continuous presence in Europe when the company won the first place in a plowing contest there. Case at this time developed a wide line of products: threshers, binders, graders, water tanks, plows, buggies, and even automobiles.

By 1929, Case had expanded to Australia, Mexico, Sweden, and other countries.

Treshing History

Before any form of mechanical threshing was invented, threshing grain was done by beating bundles of grain on the barn threshing floor. A flail was used for this laborious job, consisting of a long handle fastened by rope or rawhide to a shorter club. After the flailing, the straw was raked off. A flail was an invention that replaced the prior way of doing things, which was either beating the grain on the floor or using a stick.

Then a winnowing basket was used to throw the remaining chaff and grain kernels in the air, the wind blowing the lighter chaff aside, the heavier grain falling down to be collected. The large barn double doors on both ends of the threshing floor would be open for maximum airflow.

It has been claimed that a man could thresh about 7 bushels of grain a day with the flail!

Ground Hog Thresher

The ground hog thresher is an early form of mechanized grain threshing, invented in 1788. It consists of a rotating iron drum with finger-like spikes and a fixed concave below the drum. The machine combines threshing with fanning, breaking the grain into its parts and separating them from the straw.